In Baltmet we believe quality, ability and efficiency, thus providing a full service package to out customers is essential for a smooth and hassle free process.

Engineering

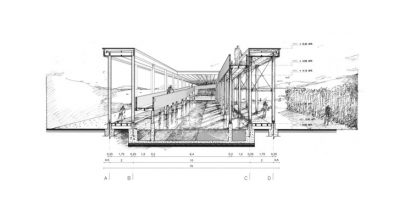

- Designing wide range of steel construction buildings

- Steel construction adaptation for every country

- Existing structural projects weight decreasing

- Redesigning existing projects

- Non-standard structures on customers demand.

Production

- Production of steel constructions

- Steel cutting, welding, processing

- Quality checking

- Surface treatment (Steel blasting, painting e.t.c)

- Packing

Construction

- Project management by certified and highly experienced experts

- Steel construction erection and assembling

- Quality control, geodetic measurements

- Frame cladding

We offer wide range of engineering services to our customers.

Our skilled professionals are ready to provide our clients with the best engineering solutions in a professional and timely manner.

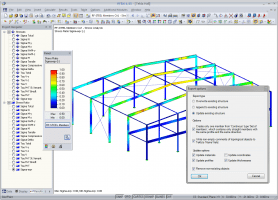

In our projects we use leading 3D software such as:

- Tekla

- AutoCAD

We offer:

- Complete designing of products/constructions – this includes all activities needed to design products (calculating the weight, pressure, load capacity; general 3D layouts of the projects; detail drawings, etc.)

- Production drawings – based on the client’s layout we make designs needed for production (mainly based on Tekla and/or CAD layouts, KM, KMD).

All steel constructions are made in-house in our production facilities, which fully correspond with EU standards.

Precise and highly effective equipment allows us to propose best price and delivery time on market.

Baltmet offers the following services:

- Welding – MIG/MAG, TIG

- Cutting/turning operations – band saws, CNC machining, lathe turning, shearing, plasma cutting, punching

- Bending – rolling, coping, roll forming

- Drilling – drill press, side drilling

- Surface preparation and painting – shot and sand blasting, prime coating, painting, powder coating, plating, fireproof coatings

- Reinforcement steel – bending, frame/carcass welding

Baltmet offers the possibility to order additional quality control services.

These are:

- Non-Destructive Testing:

- UT- ultrasonic testing

- RT- radio-graphic testing

- MT- magnetic particle testing

- VT- visual testing

- LT- leakage testing

- PT- penetration testing

- Destructive Testing:

- TT- tensile tests

- IT- Sharp impact tests

- BT- bending tests

- FLT- flattening tests

- FT- fracture tests of welds

- HBT, HVT- Brinell, Vickers and Rockwell hardness tests (in the laboratory and at the client’s site)

- MGT- metallographic inspections (macroscopic, microscopic, with and without preparation of test coupon)

- ETCH- etching test of metal coat

- CA- chemical and carbide analysis of metals and alloys

Each constructions are supplied with documentation according to European norms (Steel certificates, Welding passports, testing results and assembling drawings)

Logistics constitutes an essential part of the supply network. In conjunction to that Baltmet provides timely and effective transport to any corner of EU.

We solve all our transportation issues as follows:

- On land

- On water

- On rail

Baltmet offers full assembly and construction of our products.

Our technology and construction solutions allow for fast assembly process which makes work efficient and economically attractive for our customer.